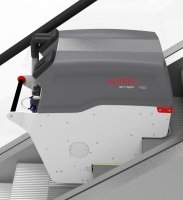

Escalator and Travelator cleaning machine

-

What are the differences between the STEP 100 and the Rotomac 360?

The first thing to say is that the STEP 100 is the follow up model of the Rotomac 360. That means that the STEP 100 has improvements over the Rotomac 360. The main aim that we had when we were working on the STEP 100 was the cleaning speed. Through the adjustment of the water-chemical detergent, more brushes and a optimized suction system we could reduce the cleaning time.

-

How long does it take to clean one escalator with the STEP 100?

The cleaning time depends on the amount of single steps that your escalator has and the amount of dirt that is on each step. On an average European escalator (with 80 single steps) you can clean an escalator – if you clean it regularly (in program 1 of 3) – in approximately 90 minutes.

-

How long does it take to clean one escalator with the Rotomac 360?

The cleaning time depends on the amount of single steps that your escalator has and the amount of dirt that is on each step. On an average European escalator (with 80 single steps) you can clean an escalator – if you clean it regularly (in program 1 of 3) – in approximately 130 minutes.

-

How long does it take to clean one escalator or travelator with the TRAVEL 600?

Here it depends on the length, the speed and the amount of dirt that you have on the escalator or travelator. If for example a travelator needs 2 minutes to make a complete cycle and you go to clean regularly it may take you approximately 30 minutes (when you clean an escalator you can only clean the steps and not the risers).

-

Are there differences in how to use the STEP 100, Rotomac 360 und TRAVEL 600?

Yes there are differences. The STEP 100 and the Rotomac 360 are made for escalators. You have to place them on the escalator and “climb” with the machine step by step. You can do this by pressing a button. On each step you have to start a cleaning cycle before you can place the machine on the next steps. When you have reached the top of the escalator you need the key for the escalator to bring the machine down with the escalator. The TRAVEL 600 has to be placed in front of the escalator or travelator. Then you have to activate the brakes and press the start button. Then the cleaning head will go down and clean the escalator or travelator while it is running.

-

What is the difference between the STEP 100, STEP 110 and STEP 150?

Both the STEP 150 and the STEP 110 have the new brush system. This has 18 instead of 15 brushes. It also has a new layout so that the machines are able to achieve faster cleaning results.

The machines also get new internal parts that make the machine start faster than before.

The STEP 150 uses as Touch display with information about Trouble shooting, how to use etc. In addition, you have the possibility to adjust the cleaning time better to the amount of dirt that is on the escalator. -

What is the difference between the STEP 150 and STEP 110?

The machines have different user interfaces. While the STEP 110 uses buttons the STEP 150 uses a Touch display. This has several differences: first advantage is that additional information’s are used on the display. As a second advantage you can reduce the cleaning time by adjusting it more exact to the amount of dirt that is on the escalator.

With the STEP 110 you can choose between 3 cleaning times (per cycle): 15 sec, 27 sec and 39 sec. The STEP 150 can be adjusted second wise from 12 sec to 60 sec. It is also possible to adjust the amount of water and chemical that is sprayed on the escalator by ±10% (+10% starts to work from 25 sec). -

When does the STEP 150 stars to make sense?

The main rule is: The more escalators you have to clean in a year the more sense it makes. The reason is that you can choose the cleaning program second wise while you have the gaps in cleaning time with the STEP 110 (1st program: 15 sec, 2nd program: 27 sec and 3rd program: 39 sec). To calculate the cleaning time, you can rough calculation:

- A = Number of steps that you have installed in the escalator

- Z = used cleaning cycle time in sec (with the STEP 150 you can choose between 12 and 60 sec. With the STEP 110 you can choose 15, 27 or 39 sec)

The formula is like that:

Cleaning time T = A x 2 x Z + A x 2 x 15 = 2A x (Z + 15)

Single disc machines

-

Can we use the JU-Single disc machine´s parts to repair the old Sorma single disc machines?

Yes. We can deliver every spare part for the Sorma A13 and Sorma A17 SL. For the Sorma A16 we only have some parts that you can use.

-

What are the differences between the JU 17 S, the JU 17 FU and the JU 17 HR?

The JU 17 S is the original Sorma A 17 SL in terms of weight, rotation speed etc. Die JU 17 FU and the JU 17 HR are multi-speed machines where you can adjust the rotation speed.

-

What is the difference between the JU 17 FU and the JU 17 HR?

The difference is the rotation speed that you can do with the machines. With the JU 17 FU you can choose between 90 up to 190 rpm. With the JU 17 HR you can choose all the rotation speeds between 150 up to 280 rpm.